Remote Maintenance of HVACTCCR-NET™

Remote Maintenance of HVACTCCR-NET™

- Provider

- Carrier Japan Corporation

Factories, data centers, buildings, facilities...all require effective heat source and air conditioning management for their sound operation―and any failure of those systems can directly impact on business. Our scalable solutions support management and maintenance, and extend service life while reducing labor costs.

The service monitors the main functions of the equipment in real time, 24/365. Our customers enjoy numerous benefits:

- Consistent reliability

- Extended equipment life

- Failure prevention

- Safety monitoring

- Extended energy-saving performance

Our product lineup offers a wide range of supply temperatures and capacities, supported by services only we can provide.

For example, analysis of accumulated monitoring data can determine how a customer uses equipment, providing the basis for measures that improve operating efficiency. When equipment is replaced, we can factor the customer's circumstances into a proposal for heat source air conditioning equipment that delivers a high return on investment.

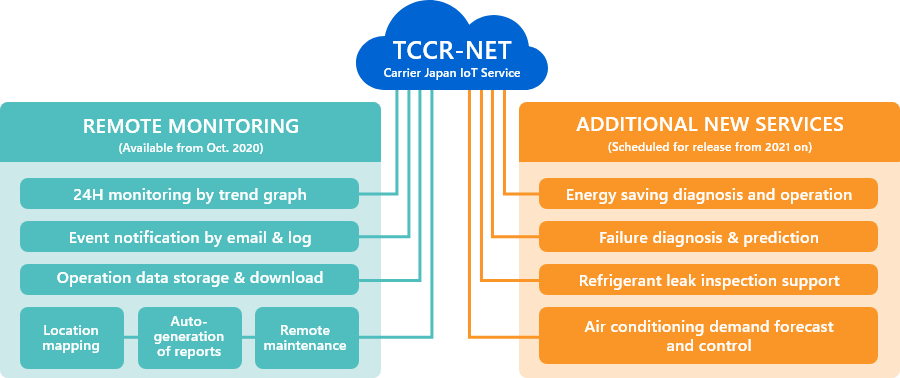

TCCR-NET™ is an IoT service that delivers remote maintenance service for heat source and air-conditioning systems. Features already include round the clock remote monitoring for abnormalities, and remote operation, and we are developing new ones. By strengthening the service, which is mainly cloud-based and delivered via the web, in areas including situational analysis, load demand forecasting and failure prediction (refrigerant leak inspection), we aim to further meet customer needs and contribute to reduced management costs and higher added value.

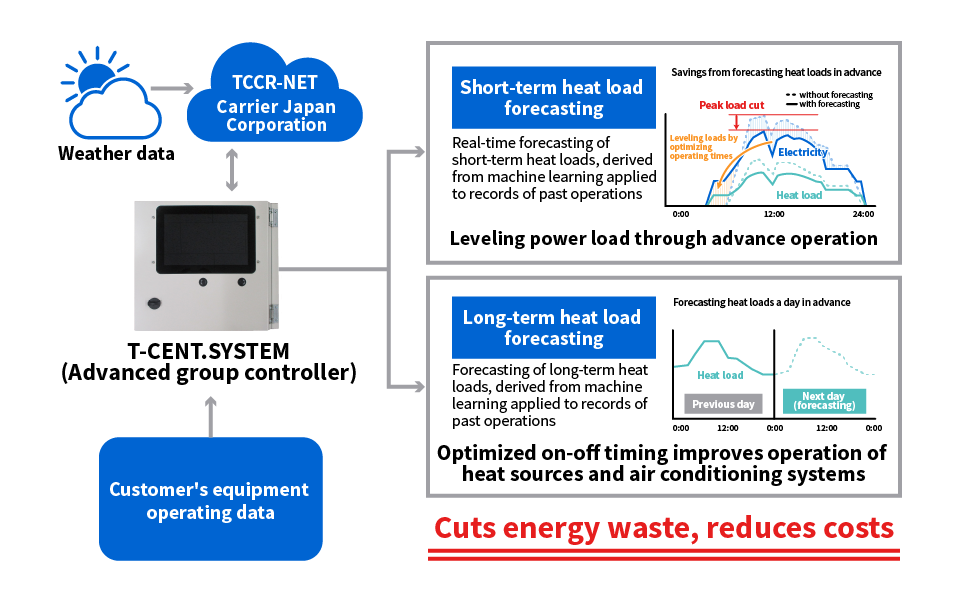

We use the customer's operating data to predict short- and long-term heat loads, optimize on/off timing of the heat source and air conditioning system, and reduce energy waste through operational improvements.

Demand forecasting service

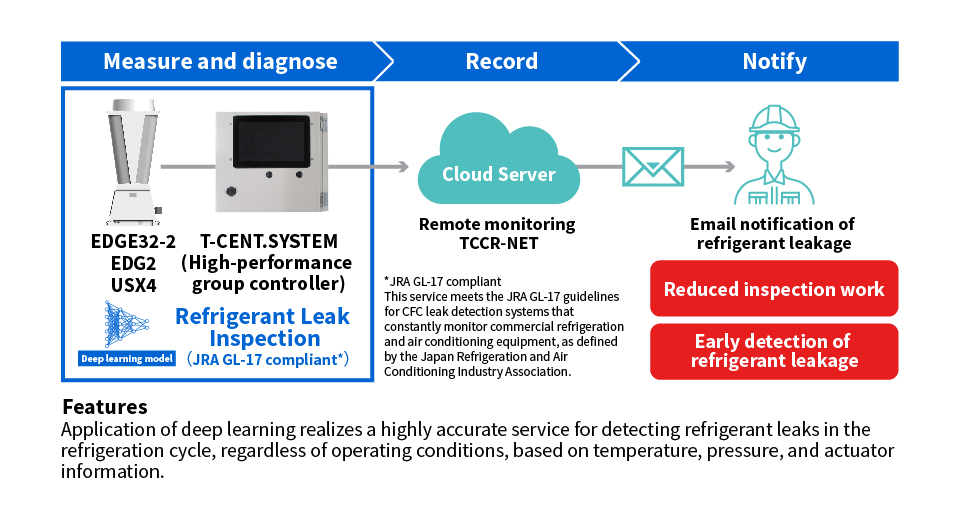

Early detection of leaks reduces loss of refrigerant from the customer's heat source equipment, and curbs higher power consumption and capacity shortages caused by degraded heat source equipment operating efficiency.

New refrigerant leak diagnostic technology, developed with deep learning, is combined with data storage on TCCR-NET and an administrator e-mail notification function in a refrigerant leak detection system compliant with the Japan Refrigeration and Air Conditioning Industry Association's "Guidelines for CFC Leak Detection System by Constant Monitoring of Commercial Refrigeration and Air Conditioning Equipment" (JRA GL-17).

Refrigerant leak inspection

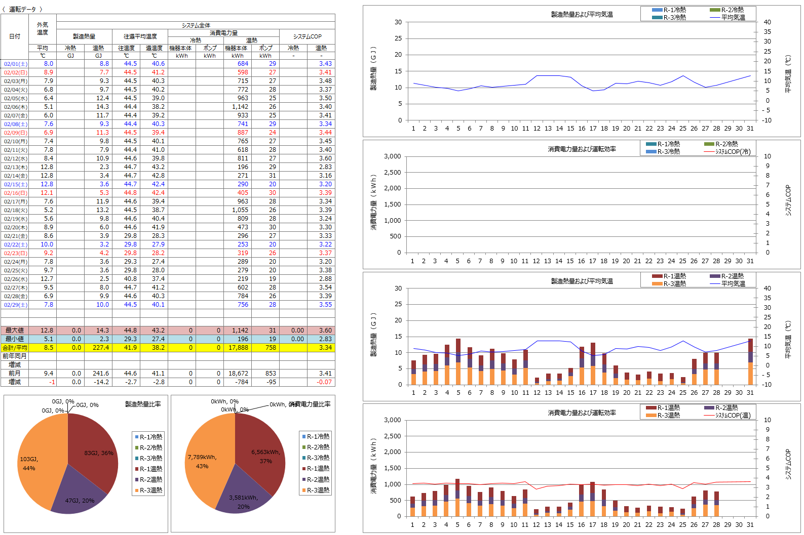

We already offer a web-based analysis report service that displays tables and graphs aggregating measurements such as outside temperatures, heat production, and power consumption, and the detailed data behind them.

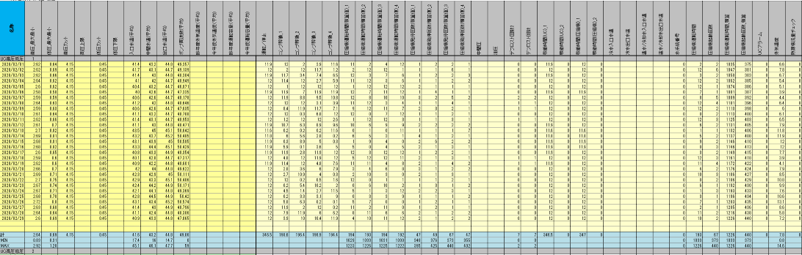

Screen sample for aggregation result (sample shown in Japanese)

Screen sample for detailed data (sample shown in Japanese)

TOSHIBA SPINEX

The brand name for industrial IoT services compliant with the Toshiba IoT Reference Architecture.

TOSHIBA SPINEX contributes to sustainable value creation. Visit Our strategy.

Thoughts behind the name SPINEX

SPINE + X

The spine is our body’s central support structure, our core, home to the spinal cord that radiates nerves throughout or bodies. In the same way as the nervous system allows us to experience the world, edge computing delivers fast decisions in data processing by distributing sensing and control to every point where it is needed.

Our spine makes us strong and agile. We can do the same for your business, and contribute to society, by providing an essential industrial IoT framework that supports your people and operations with fast, appropriate on-site processing.

The X of SPINEX represents eXperience and eXpansion, and the crossover with other value creators and services. This is how we will create the future with TOSHIBA SPINEX Services.

Two pillars of the Toshiba IoT Reference Architecture compliance standard

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.