VenetDCPDistributed Co-simulation Platform

VenetDCPDistributed Co-simulation Platform

- Provider

- Toshiba Digital Solutions Corporation

CASE - Connected, Autonomous, Shared, Electric - is revolutionizing the automobile industry, and accelerating the uptake of model-based development (MBD) by developers of automotive control systems.

MBD is a development method that simulates models of in-vehicle components and traffic environments, including roads, pedestrians, bicycles, traffic signs, and other vehicles. Until now, successful application of MBD has largely been limited to design of individual automotive control units.

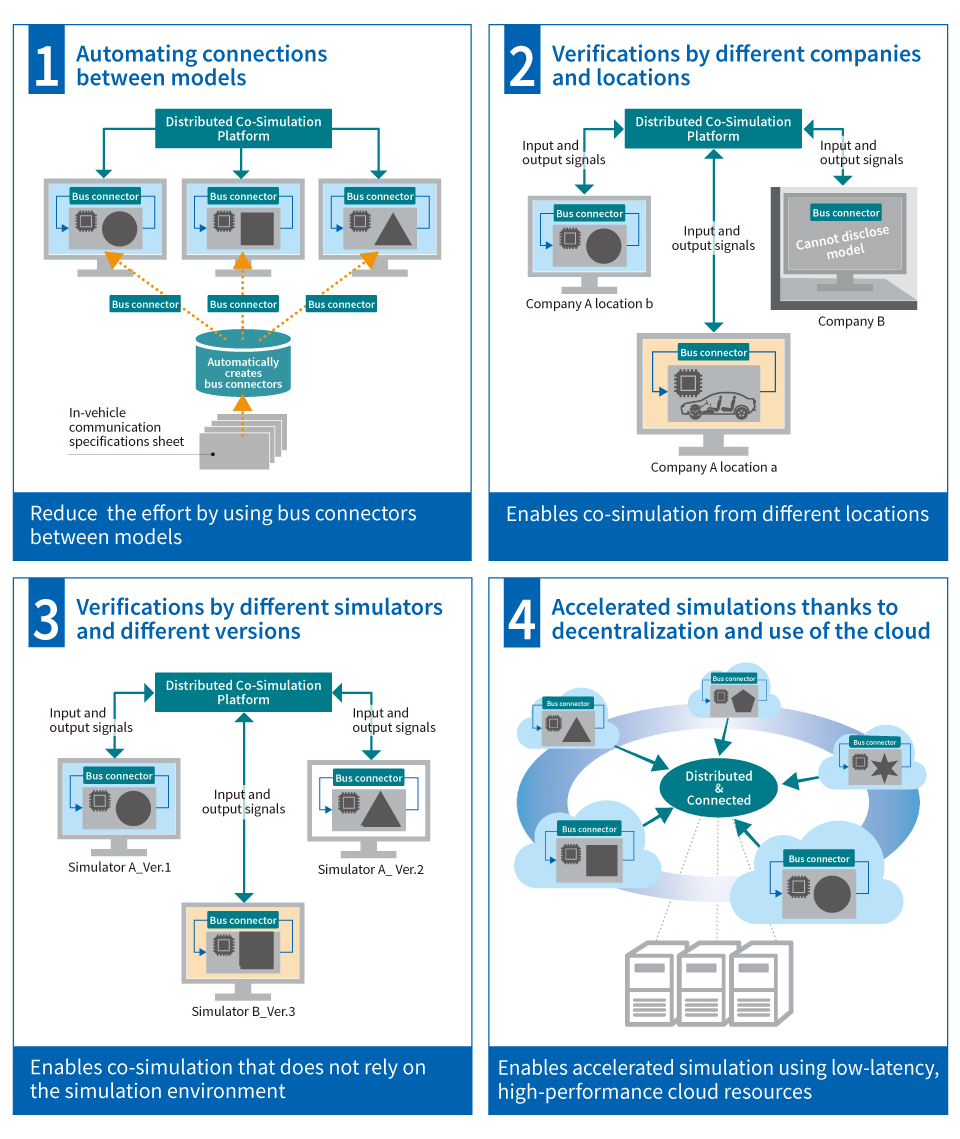

As more car manufacturers and suppliers see the power of MBD, our Distributed Co-Simulation Platform supports broader, larger-scale application with a joint verification environment that links multiple models, development tools and companies in cyberspace. This realizes earlier verifications of complex automotive control systems connected to multiple systems, such as advanced driving assist and autonomous driving. The platform improves quality and wins dramatic boosts in productivity.

Vehicles now incorporate numerous components from multiple suppliers, and the automotive industry must simulate interactions among multiple models. This throws up new challenges, including the difficulty of cooperation among multiple suppliers and connecting models.

Since models embody their design specifications, suppliers are unwilling to share them with third parties. On top of that, connecting the thousands of signals (variables) transmitted across control systems is a highly complicated task.

Even if these issues are overcome, processing a simulation linking many cooperating models is a heavy load that takes a long time to execute on a single PC.

- It’s hard to connect models

Connecting multiple signal lines without any mistakes is a challenge, and it takes considerable man-hours to investigate whether a problem is a connection error or a bug.

- Model is not disclosed

Design data for models is confidential information belonging to each company, and they must connect their development environments without disclosing this information to other companies.

- Simulation is slow

Operation slows and it takes time to execute simulations when combining multiple models on one computer.

TOSHIBA SPINEX

The brand name for industrial IoT services compliant with the Toshiba IoT Reference Architecture.

TOSHIBA SPINEX contributes to sustainable value creation. Visit Our strategy.

Thoughts behind the name SPINEX

SPINE + X

The spine is our body’s central support structure, our core, home to the spinal cord that radiates nerves throughout or bodies. In the same way as the nervous system allows us to experience the world, edge computing delivers fast decisions in data processing by distributing sensing and control to every point where it is needed.

Our spine makes us strong and agile. We can do the same for your business, and contribute to society, by providing an essential industrial IoT framework that supports your people and operations with fast, appropriate on-site processing.

The X of SPINEX represents eXperience and eXpansion, and the crossover with other value creators and services. This is how we will create the future with TOSHIBA SPINEX Services.

Two pillars of the Toshiba IoT Reference Architecture compliance standard

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.