IoT Equipment Cloud Service for Industrial Equipment Manufacturers

IoT Equipment Cloud Service for Industrial Equipment Manufacturers

- Provider

- Toshiba Digital Solutions Corporation

Manufacturers of equipment for factories and industrial plants must increasingly address issues like the globalization of delivery destinations, aging maintenance and support personnel, and shortages of human resources.

This service enhances the efficiency of maintenance services by remotely monitoring the operation status of installed products.

This remote monitoring service is based on an asset integration data platform derived from Toshiba Group's many years of experience and knowledge in remote monitoring and maintenance. It helps equipment manufacturers to improve the responsiveness of maintenance work and to provide proposal-based services for maintenance and purchasing replacement products and supplies. It also enables the development of products tailored to customer needs.

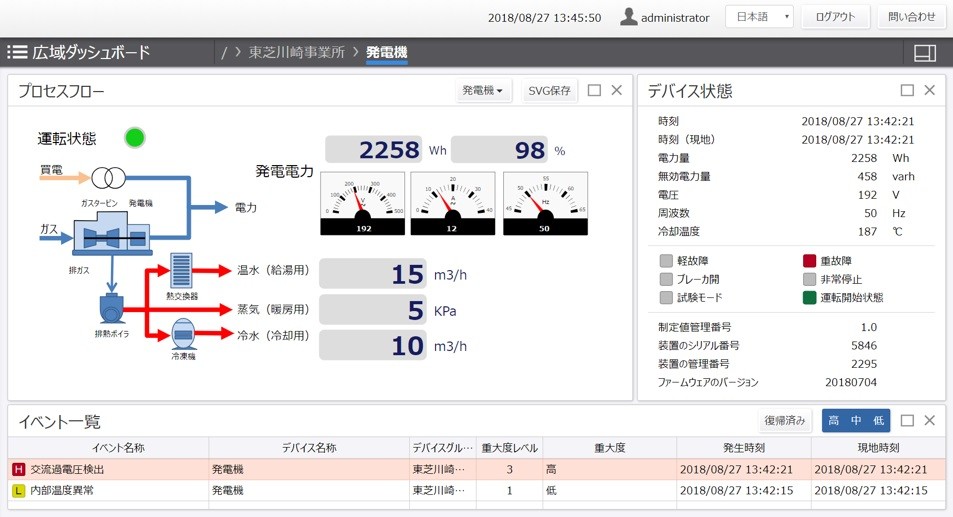

The visualization screen is intuitive and easy to use, and applies UXD (User eXperience Design) to achieve high operability.

A bird's-eye view of facilities and equipment locations around the world.

A flow diagram of monitored target equipment connected in a series of processes, such as factory utility equipment.

TOSHIBA SPINEX

The brand name for industrial IoT services compliant with the Toshiba IoT Reference Architecture.

TOSHIBA SPINEX contributes to sustainable value creation. Visit Our strategy.

Thoughts behind the name SPINEX

SPINE + X

The spine is our body’s central support structure, our core, home to the spinal cord that radiates nerves throughout or bodies. In the same way as the nervous system allows us to experience the world, edge computing delivers fast decisions in data processing by distributing sensing and control to every point where it is needed.

Our spine makes us strong and agile. We can do the same for your business, and contribute to society, by providing an essential industrial IoT framework that supports your people and operations with fast, appropriate on-site processing.

The X of SPINEX represents eXperience and eXpansion, and the crossover with other value creators and services. This is how we will create the future with TOSHIBA SPINEX Services.

Two pillars of the Toshiba IoT Reference Architecture compliance standard

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.