Manufacturing IoT Cloud Service

Manufacturing IoT Cloud Service

- Provider

- Toshiba Digital Solutions Corporation

Optimal utilization of information at manufacturing sites requires visualization and analysis not only of IoT data but also other production-related data, covering processing, quality, operations, etc. This all needs to be done on-site, quickly and easily.

Expertise in manufacturing, cultivated over many years, underpins Toshiba’s manufacturing IoT cloud service, which supports the storage and utilization of IoT data in manufacturing.

Our integrated data model rapidly links IoT data with business data generated in manufacturing processes. It quickly visualizes manufacturing status changes and traceability, and contributes to productivity and quality improvement.

The system is scalable, providing just what is needed, when it is needed. You can start storing and using IoT data from just a single device or process, minimizing initial investment. From there, you can gradually expand the scope of application to production lines and factories as a whole, according to the size of your business.

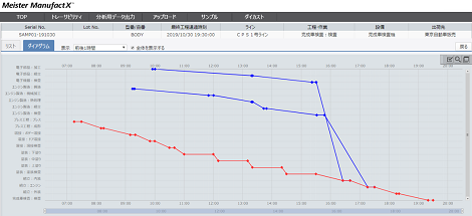

Standard screens frequently used at production sites are based on an integrated data model, and deliver quick and comprehensive visualization.

A traceability screen that visualizes a product’s manufacturing history

The dashboard showing production amounts, numbers of failures, equipment operation results, and stoppage factors

TOSHIBA SPINEX

The brand name for industrial IoT services compliant with the Toshiba IoT Reference Architecture.

TOSHIBA SPINEX contributes to sustainable value creation. Visit Our strategy.

Thoughts behind the name SPINEX

SPINE + X

The spine is our body’s central support structure, our core, home to the spinal cord that radiates nerves throughout or bodies. In the same way as the nervous system allows us to experience the world, edge computing delivers fast decisions in data processing by distributing sensing and control to every point where it is needed.

Our spine makes us strong and agile. We can do the same for your business, and contribute to society, by providing an essential industrial IoT framework that supports your people and operations with fast, appropriate on-site processing.

The X of SPINEX represents eXperience and eXpansion, and the crossover with other value creators and services. This is how we will create the future with TOSHIBA SPINEX Services.

Two pillars of the Toshiba IoT Reference Architecture compliance standard

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.