Dashboard

for Power PlantsOperation status visualization

Dashboard

for Power PlantsOperation status visualization

- Provider

- Toshiba Energy Systems & Solutions Corporation

Most utility companies operate multiple power plants. Doing so efficiently requires cross-checking of a lot of information, including operations data, specifications, equipment and spare parts, plus checks of individual systems. All of which poses the risk of higher operation and maintenance costs. As IoT technology evolves and takes its place on the global stage, utilities are very interested in using it to reduce costs, and have started digitizing a range of data. However, this has not yet improved business efficiency.

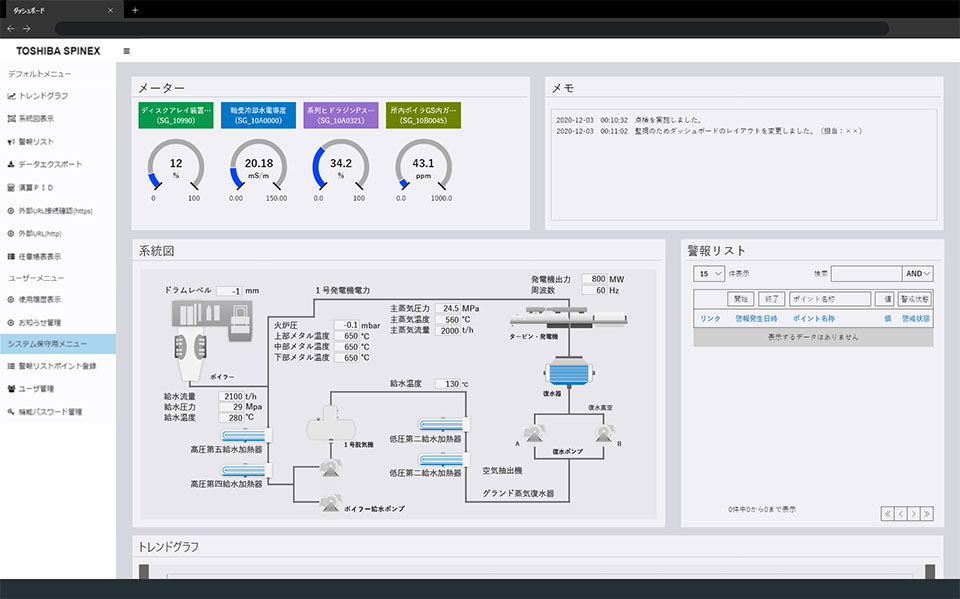

Integration of digitized data has the power to visualize and instantly clarify the information power plant operators need, from equipment status to management level. The service can handle data from multiple plants, covering areas including operation data, specifications, equipment ledger and parts inventory. Seamless linking can significantly reduce the time required for multiple series of maintenance operations.

This is a Dashboard, one of the building blocks of TOSHIBA SPINEX for Energy. See also Related Services below.

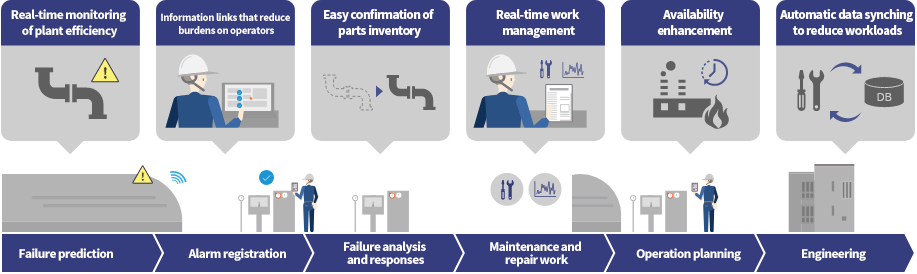

If a problem arises, the dashboard can detect the failure or operational event in the system, ensure operators quickly grasp the workflow needed to handle the problem, then take them through the flow. The result is fast responses to day-to-day failures and minimized maintenance costs.

- Our microservice architecture supports selection and linking of data and services that meet customer needs

- Our services can be deployed on-site or in the cloud, or even in a hybrid configuration.

- Our decentralized database architecture facilitates flexible combinations of data flows and services.

- Our information model, derived from long experience, a truly extensive record of equipment deliveries, and engineering know-how accumulated in the field, supports us in adding semantic information to data to improve its reusability.

- Our technologies for detecting locations and abnormalities with data from camera images can also be used to empower Dashboard for Substations, to improve data reusability and improve work efficiency.

TOSHIBA SPINEX

The brand name for industrial IoT services compliant with the Toshiba IoT Reference Architecture.

TOSHIBA SPINEX contributes to sustainable value creation. Visit Our strategy.

Thoughts behind the name SPINEX

SPINE + X

The spine is our body’s central support structure, our core, home to the spinal cord that radiates nerves throughout or bodies. In the same way as the nervous system allows us to experience the world, edge computing delivers fast decisions in data processing by distributing sensing and control to every point where it is needed.

Our spine makes us strong and agile. We can do the same for your business, and contribute to society, by providing an essential industrial IoT framework that supports your people and operations with fast, appropriate on-site processing.

The X of SPINEX represents eXperience and eXpansion, and the crossover with other value creators and services. This is how we will create the future with TOSHIBA SPINEX Services.

Two pillars of the Toshiba IoT Reference Architecture compliance standard

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.