Dashboard for SubstationsOperation status visualization

Dashboard for SubstationsOperation status visualization

- Provider

- Toshiba Energy Systems & Solutions Corporation

Increasing costs due to operational complexity and legacy technologies

Transmission and distribution operators typically operate several power grid facilities, and ensure stable operation through simultaneous monitoring of a wide variety of data, including operating status, facility logs, parts inventory and engineering drawings. Difficulties inherent in surveying such large and diverse data pose the risk of increased operational and maintenance costs.

The retirement of senior engineers can result in the loss of on-site know-how on substation operations and maintenance. Also, with the global penetration of IoT, operators of T&D services are increasingly interested in leveraging new technologies and on-site data gathered through digital transformation (DX) to improve operational efficiency.

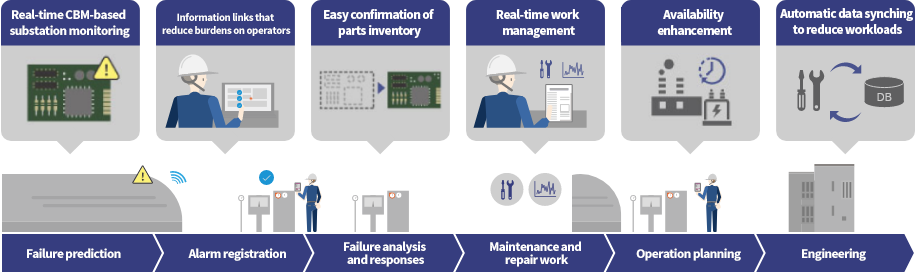

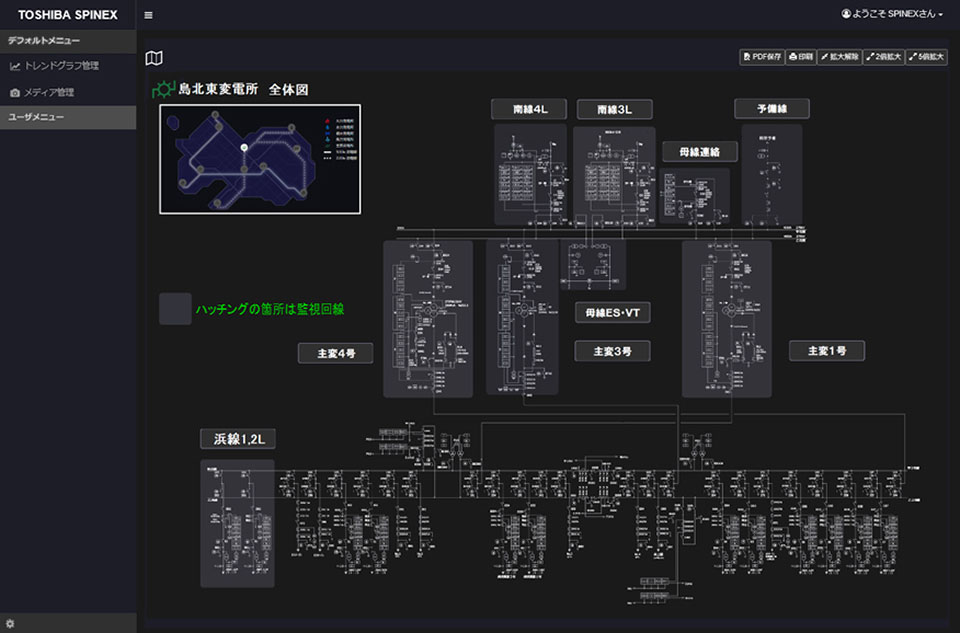

By connecting a variety of digitized data from numerous substation facilities (operational data, incident analysis flow, blueprints, facility logs, spare parts list), we make it possible to grasp at a glance the status of a substation. It is also possible, without the use of programming skills, to define their own company's workflow and track incidents through the data.

Connecting various digitized data from numerous substations allows a substation’s status to be taken in at a glance. Operators can define company workflows without any need for programming skills, and also track appropriate workflows for responding to any incidents that suddenly occur.

This is a Dashboard, one of the building blocks of TOSHIBA SPINEX for Energy. See also Related Services below.

The Dashboard detects and displays system abnormalities, along with the workflow (troubleshooting method) required to counteract them. This fast, accurate response to problems and failures minimizes equipment downtime.

- Our microservice architecture supports selection and linking of data and services that meet customer needs.

- Our services can be deployed on-site or in the cloud, or even in a hybrid configuration.

- Our decentralized database architecture facilitates flexible combinations of data flows and services.

- Our information model, derived from long experience, a truly extensive record of equipment deliveries, and engineering know-how accumulated in the field, supports us in adding semantic information to data to improve its reusability.

TOSHIBA SPINEX

The brand name for industrial IoT services compliant with the Toshiba IoT Reference Architecture.

TOSHIBA SPINEX contributes to sustainable value creation. Visit Our strategy.

Thoughts behind the name SPINEX

SPINE + X

The spine is our body’s central support structure, our core, home to the spinal cord that radiates nerves throughout or bodies. In the same way as the nervous system allows us to experience the world, edge computing delivers fast decisions in data processing by distributing sensing and control to every point where it is needed.

Our spine makes us strong and agile. We can do the same for your business, and contribute to society, by providing an essential industrial IoT framework that supports your people and operations with fast, appropriate on-site processing.

The X of SPINEX represents eXperience and eXpansion, and the crossover with other value creators and services. This is how we will create the future with TOSHIBA SPINEX Services.

Two pillars of the Toshiba IoT Reference Architecture compliance standard

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.