EtaPRO™ APREarly Detection of Failure in Operation Data

EtaPRO™ APREarly Detection of Failure in Operation Data

- Provider

- Toshiba Energy Systems & Solutions Corporation

Digitization is underway, but we have not yet improved operational efficiencies

Emergency shutdowns due to failures have a tremendous impact on power plant operations. Generating capacity is lost, and emergency repairs are necessary. Plant operators following the global development and adoption of IoT technologies are increasingly interested in leveraging them to reduce operation downtimes. However, although a variety of data can be digitized and amassed, exploiting it to the full to improve operational efficiency remains a challenge.

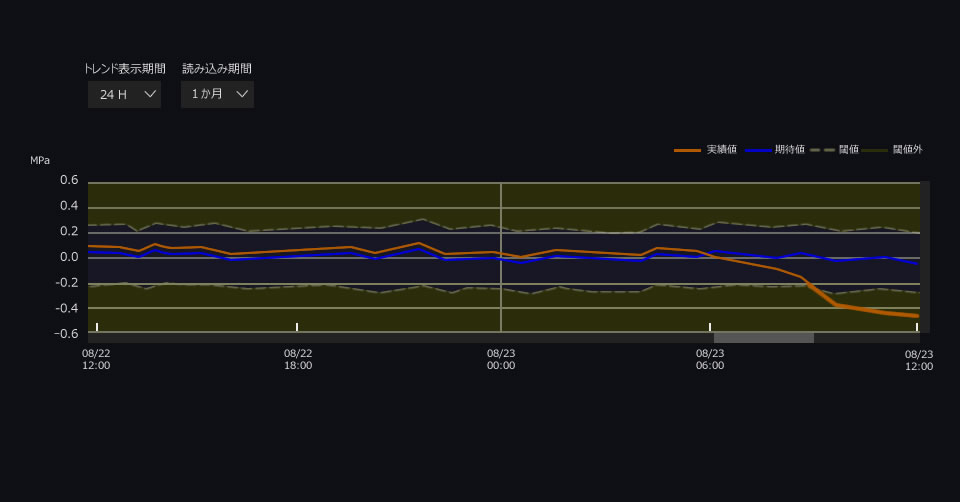

We build models that correlate past data from normal operations with current data in real time, and that can detect differences from past behavior and predict failures before they happen.

This is a microservice, one of the building blocks of TOSHIBA SPINEX for Energy. See also Related Services below.

Accurate prediction of when failures will happen allows planning for equipment downtimes and inspection, improves availability rates and reduces opportunity losses.

- Extensive experience in plant manufacture supports us in building accurate models with the appropriate assets

- Real time visualization of actual data and the values predicted by the model

- We also provide tools that allow the customer to update the model, if necessary

TOSHIBA SPINEX

The brand name for industrial IoT services compliant with the Toshiba IoT Reference Architecture.

TOSHIBA SPINEX contributes to sustainable value creation. Visit Our strategy.

Thoughts behind the name SPINEX

SPINE + X

The spine is our body’s central support structure, our core, home to the spinal cord that radiates nerves throughout or bodies. In the same way as the nervous system allows us to experience the world, edge computing delivers fast decisions in data processing by distributing sensing and control to every point where it is needed.

Our spine makes us strong and agile. We can do the same for your business, and contribute to society, by providing an essential industrial IoT framework that supports your people and operations with fast, appropriate on-site processing.

The X of SPINEX represents eXperience and eXpansion, and the crossover with other value creators and services. This is how we will create the future with TOSHIBA SPINEX Services.

Two pillars of the Toshiba IoT Reference Architecture compliance standard

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.