Crack Detection

Crack Detection

- Provider

- Toshiba Energy Systems & Solutions Corporation

Headrace tunnels in hydropower plants must be inspected regularly. Detecting small surface cracks in the dark, over distances as long as several kilometers, is a long, arduous, labor intensive process.

AI processing supports inspectors by analyzing photographic images of tunnel walls to detect and visualize even minute cracks.

This is a microservice, one of the building blocks of TOSHIBA SPINEX for Energy. See also Related Services below.

- Shorter on-site maintenance times.

- On-site work is limited to acquiring image data, either stills or video, and training and know-how in identifying cracks are not requirements.

- Data recorded on-site can be locally stored in a database for later visual verification by a specialist.

- Crack detection technology that reduces on-site work, with no need for a skilled operator

- Eliminates the need for the pre-training of usual AI (machine learning)

- Uses standard image classification techniques to determine the presence or absence of cracks, and visualizes any cracks in the image

- Application not limited to tunnel walls

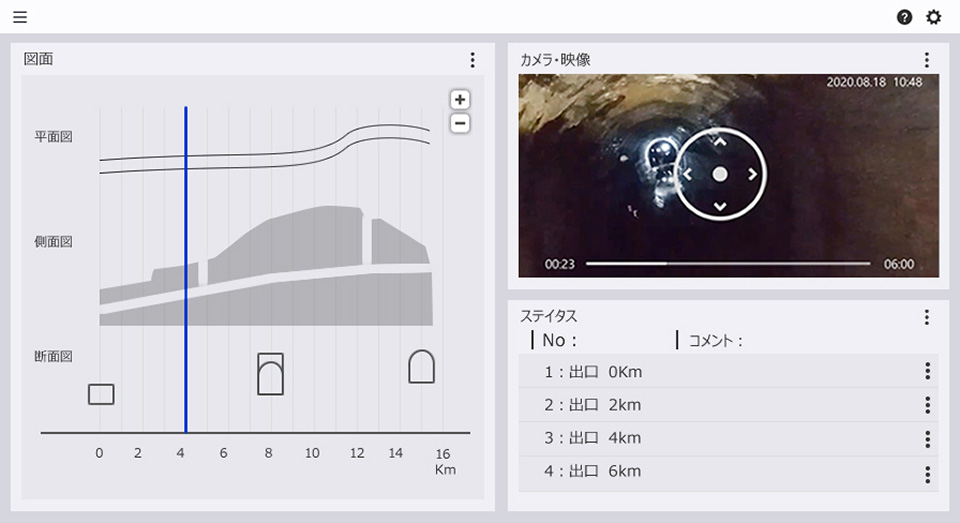

Patrol screen sample

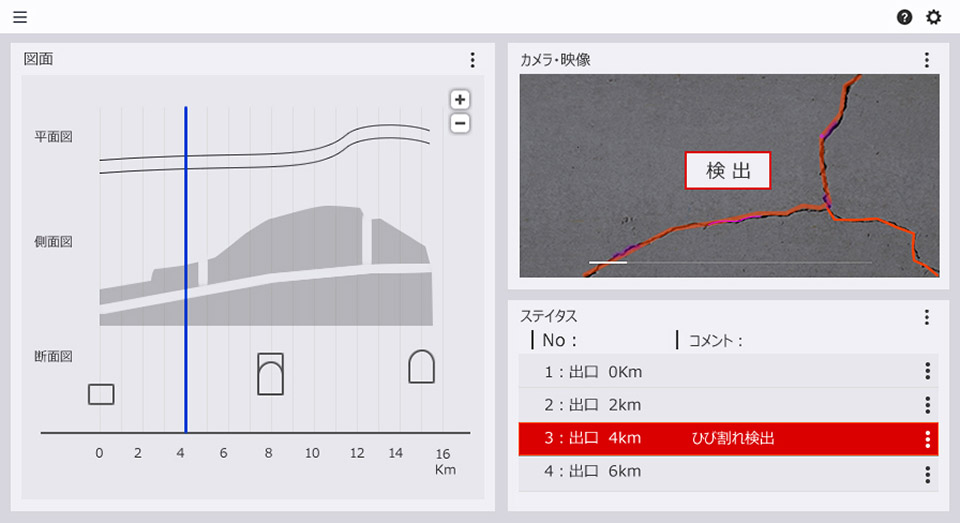

Crack detection screen sample

TOSHIBA SPINEX

The brand name for industrial IoT services compliant with the Toshiba IoT Reference Architecture.

TOSHIBA SPINEX contributes to sustainable value creation. Visit Our strategy.

Thoughts behind the name SPINEX

SPINE + X

The spine is our body’s central support structure, our core, home to the spinal cord that radiates nerves throughout or bodies. In the same way as the nervous system allows us to experience the world, edge computing delivers fast decisions in data processing by distributing sensing and control to every point where it is needed.

Our spine makes us strong and agile. We can do the same for your business, and contribute to society, by providing an essential industrial IoT framework that supports your people and operations with fast, appropriate on-site processing.

The X of SPINEX represents eXperience and eXpansion, and the crossover with other value creators and services. This is how we will create the future with TOSHIBA SPINEX Services.

Two pillars of the Toshiba IoT Reference Architecture compliance standard

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.

The service is an open interface, not closed on itself, an architecture that enables third parties to safely create value.